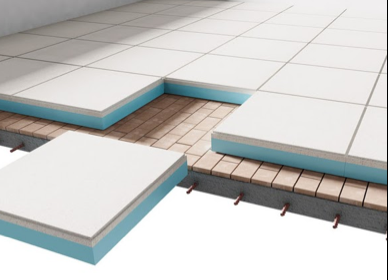

XPS + concrete plate

The needs of our customers are varied. We now present the insulation plate covers that can be exploited for an activity (pedestrian).

A base formed by XPS of different thicknesses, and a top layer of concrete of 30 mm.

Difficulties is a process with the need for measurement accuracy. A placement process in automatic XPS in the mold.

With only 30 mm of concrete obtain sufficient strength.

With only 30 mm of concrete obtain sufficient strength.